Quality Control

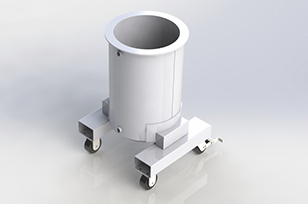

When it comes to quality, few metal fabrication services have the team, the tools or the processes in place to guarantee quality outcomes consistently. At SPEC FAB, however, we’ve invested in our quality management capabilities to ensure that our work is on spec for each and every project.

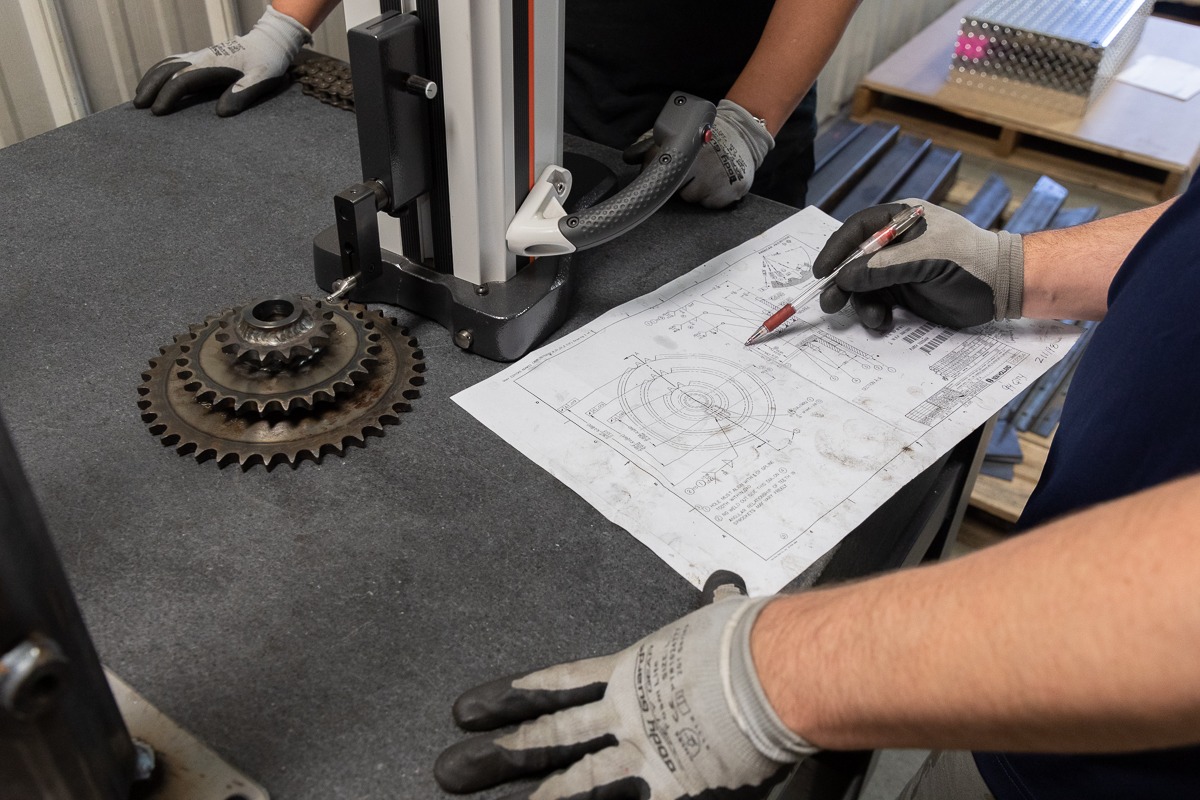

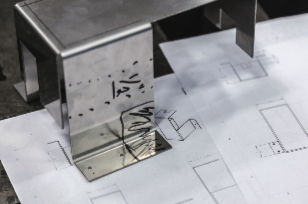

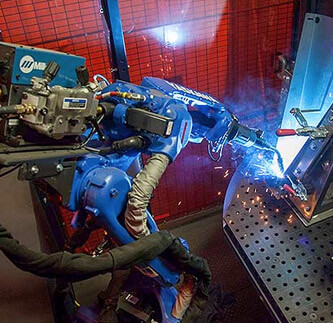

To start, each of our projects begins with collaboration. Thanks to in-house designers and project managers, we make sure drawings are accurate, and we identify potential manufacturability issues before production. Then, once jobs are in process, our certified technicians work with calibrated and tested equipment while collaborating with our broader team every step of the way. These are just a few of the ways we make sure the work we do is on spec and within tolerance on every project.

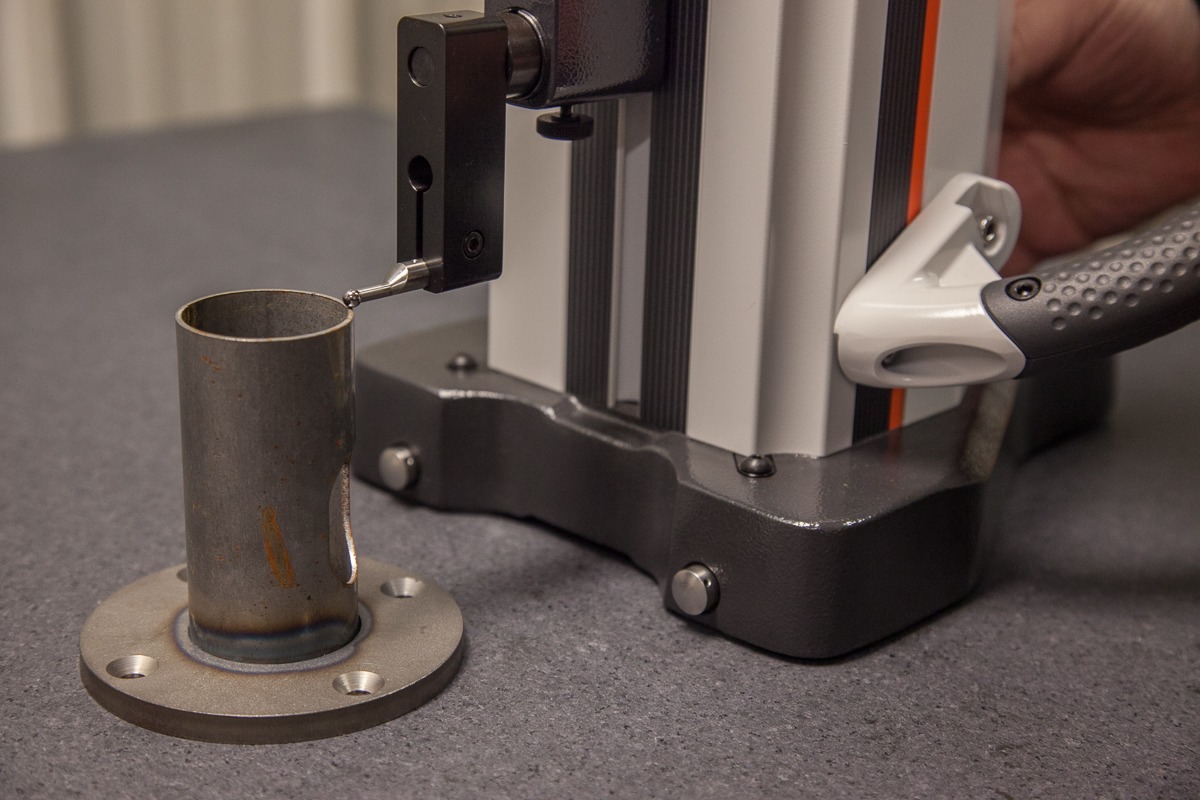

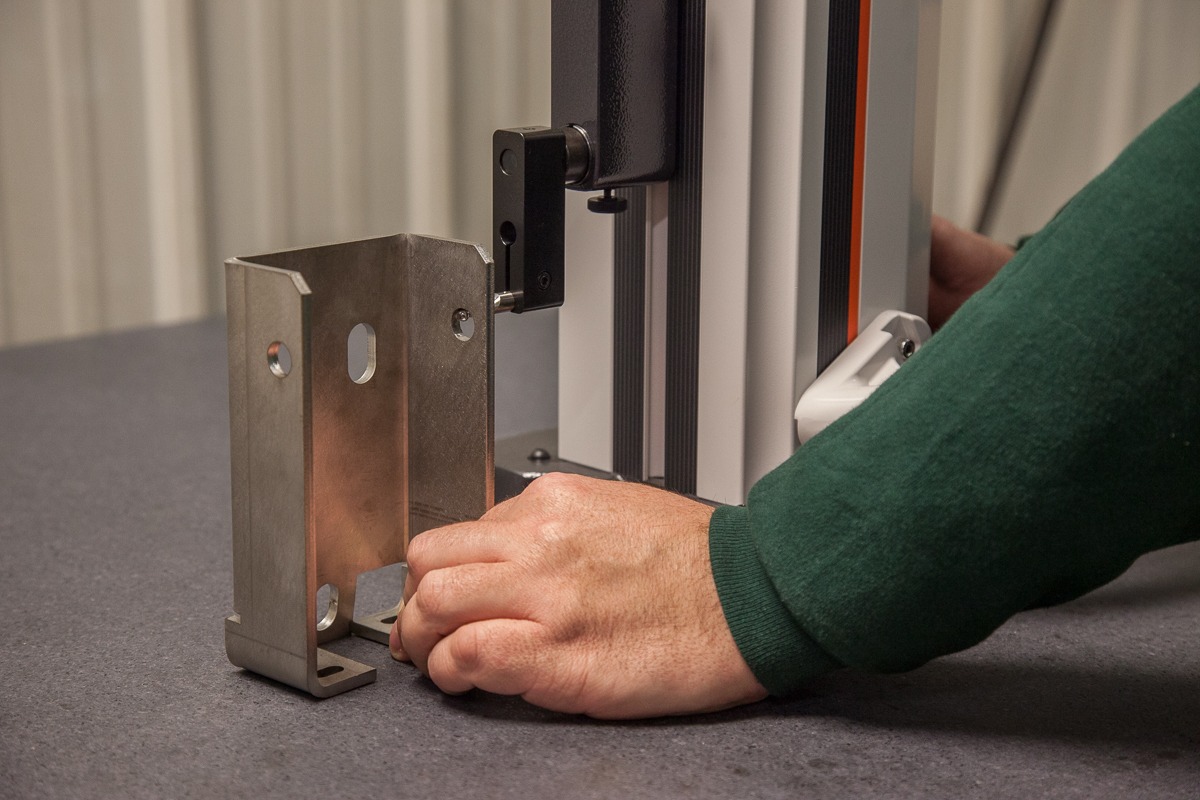

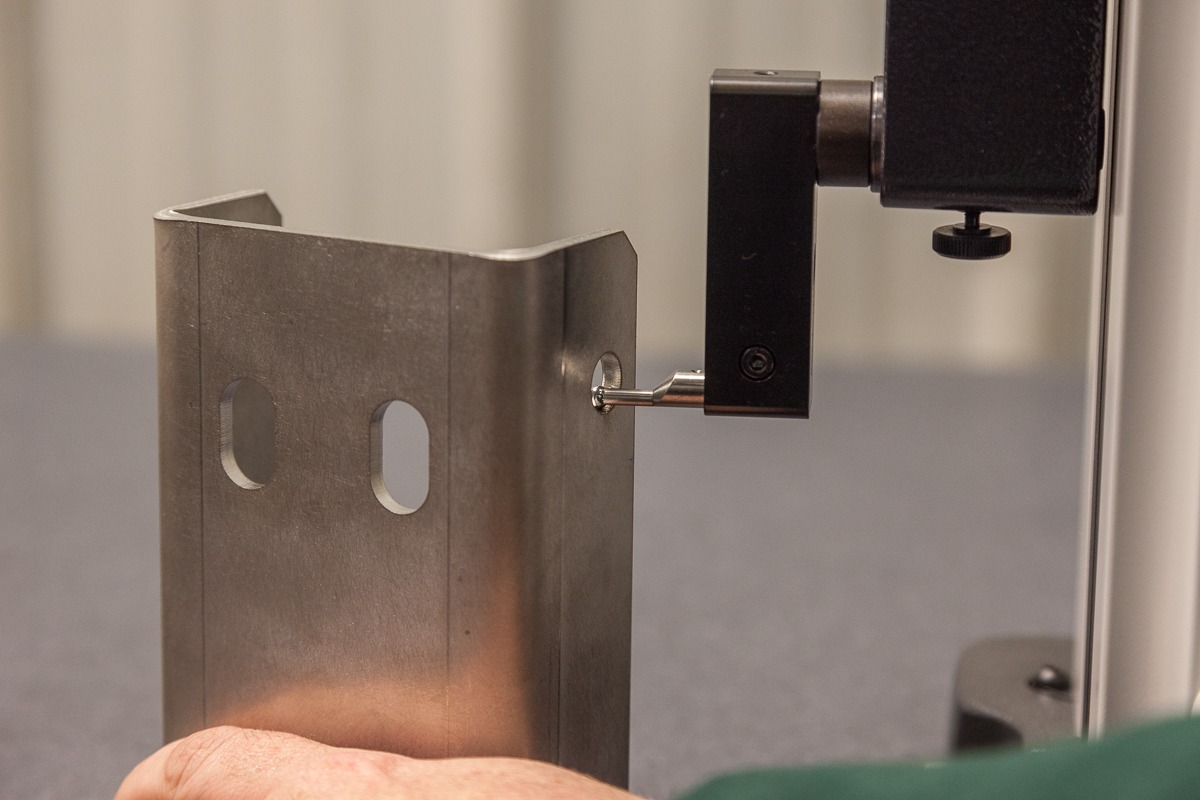

Even better, our dedicated Quality Control team is involved in every project. Using the latest QC tools, including precision measuring systems, calipers and software, and a granite table for taking precise measurements, we make sure all of our projects are fabricated correctly. When it comes to guaranteeing precise tolerances, we have systems and processes in place to check our jigs and fixtures, perform first article inspections, and make sure our work meets the project requirements.

At SPEC FAB, quality matters. And a commitment to the highest quality outcomes is baked into everything we do. From hiring to training to our equipment, tools and processes we make sure our work is top notch.

If you’re interested in learning more about our Quality Control capabilities, contact us today. Our team is standing by to answer your questions and discuss ways we can guarantee the quality of your next project.